You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plaster Mold: Bonsai Pot Casting

- Thread starter lieuz

- Start date

lieuz

Chumono

Here are some slight modifications I can apply to the pot. I chose this shape because I felt it was easy enough to make these slight changes. Should they be good, I would make another replication of it.

Here are the pot comparisons after it had a chance to dry.

The original pot is 1/4" bigger but after 8 hours, the replica pot shrank by that much.

Here's a direct difference showing the shrinkage. I expect this to be 10-12% smaller. So in the grand scheme of things, it'll just be a tad smaller which is what I actually want since I have smaller-sized trees.

Here's another pot pulled from the mold. The bottom is the first pot, the second is on top. It's currently in the queue to be fired. Super excited.

Here are the pot comparisons after it had a chance to dry.

The original pot is 1/4" bigger but after 8 hours, the replica pot shrank by that much.

Here's a direct difference showing the shrinkage. I expect this to be 10-12% smaller. So in the grand scheme of things, it'll just be a tad smaller which is what I actually want since I have smaller-sized trees.

Here's another pot pulled from the mold. The bottom is the first pot, the second is on top. It's currently in the queue to be fired. Super excited.

lieuz

Chumono

I got these back from the club president when I recently saw him. It just goes to show how much smaller these pots can get after firing.

Side by side of the original pot vs the pot pulled from 1.0.

Better size comparison. This makes me think that this is probably how the professionals shrink their pots so that there are size variations.

For the moment, I want to redo the mold for the original sakura blossom pot, given that now that I know the nuances. The next shapes I want to replicate next are moko pots.

Side by side of the original pot vs the pot pulled from 1.0.

Better size comparison. This makes me think that this is probably how the professionals shrink their pots so that there are size variations.

For the moment, I want to redo the mold for the original sakura blossom pot, given that now that I know the nuances. The next shapes I want to replicate next are moko pots.

Pitoon

Imperial Masterpiece

All clays have a shrinkage rate when fired. If you want a 10-12% smaller pot make a mold of the pot that you pulled from the first mold and continue the process. Sooner or later you can get it down to mame size

The only bad thing with molds is the storage space one needs to store them and the fact that they only last for so many pulls.

The only bad thing with molds is the storage space one needs to store them and the fact that they only last for so many pulls.

lieuz

Chumono

For sure, the storage space is going to be an issue if I made anymore molds. Do you have any pictures of your molds you can share?All clays have a shrinkage rate when fired. If you want a 10-12% smaller pot make a mold of the pot that you pulled from the first mold and continue the process. Sooner or later you can get it down to mame size

The only bad thing with molds is the storage space one needs to store them and the fact that they only last for so many pulls.

Eckhoffw

Masterpiece

That

That shit is tech. Nice work!View attachment 415495

After the 8 hour mark, the clay was firm enough for me to add my chop mark and drainage holds.

View attachment 415496

There is a support structure inside the pot that isn't shown. It's basically a sponge with a flat top and base.

View attachment 415497

Drainage holes and wire holes were applied. Note the gap in between the mold and the clay. This was a clear indication the pot has more or less separated from the mold.

View attachment 415498

Here is the pot removed from the mold with the support structure.

View attachment 415499

The ridge that was removed from the original pot was put back in.

View attachment 415500

The ridge that was removed from the original pot was put back in.

View attachment 415505

This was the profile rib for the ridge/coil of clay that ran around the pot base.

View attachment 415502

Cleaning up, I noticed there were some areas where the clay walls were off. This showed how the top warpage affected the opening.

View attachment 415503

More finishing was done to the exterior walls. That coil added back into the pot was like going full circle.

View attachment 415504

Top view. The pot is now ready for feet.

Pitoon

Imperial Masterpiece

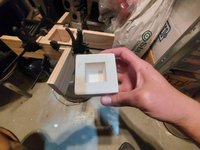

My focus is on smaller pots, mame size. Here's one I just recently did and tossed out as the plaster was old. I just got a new bag of plaster so when I get some time this weekend I will start back up with the molds.For sure, the storage space is going to be an issue if I made anymore molds. Do you have any pictures of your molds you can share?

lieuz

Chumono

Wow you really got it all figured out. That form is clean as anything!My focus is on smaller pots, mame size. Here's one I just recently did and tossed out as the plaster was old. I just got a new bag of plaster so when I get some time this weekend I will start back up with the molds.

View attachment 415548View attachment 415549View attachment 415550View attachment 415551View attachment 415552

lieuz

Chumono

Looks like you got some root stand blocks going!My focus is on smaller pots, mame size. Here's one I just recently did and tossed out as the plaster was old. I just got a new bag of plaster so when I get some time this weekend I will start back up with the molds.

View attachment 415548View attachment 415549View attachment 415550View attachment 415551View attachment 415552

19Mateo83

Masterpiece

This post is impressive. All I can say is I want one

Pitoon

Imperial Masterpiece

I wish I didn't waste my time using that old plaster. I now have to basically start all over to make that mold. Doing a one piece mold is a lot faster that was what @ABCarve mentioned earlier in the thread.Wow you really got it all figured out. That form is clean as anything!

I have a lot of projects going on......just need more time to finish them.Looks like you got some root stand blocks going!

lieuz

Chumono

No picture update but the pots have been fired to bisque and no faults have been detected.

@Pitoon I use murphy's soap as a release agent. in your experience do you use any other that may possibly work better than the soap? I say this because the soap tends to gel up for some reason and it imprints those gel'ed up bits. The larger bits I'm able to remove, but the smaller ones also leave small imprints.

@Pitoon I use murphy's soap as a release agent. in your experience do you use any other that may possibly work better than the soap? I say this because the soap tends to gel up for some reason and it imprints those gel'ed up bits. The larger bits I'm able to remove, but the smaller ones also leave small imprints.

Pitoon

Imperial Masterpiece

Murphy's Soap is technically a cleaning vegetable oil.No picture update but the pots have been fired to bisque and no faults have been detected.

@Pitoon I use murphy's soap as a release agent. in your experience do you use any other that may possibly work better than the soap? I say this because the soap tends to gel up for some reason and it imprints those gel'ed up bits. The larger bits I'm able to remove, but the smaller ones also leave small imprints.

I use an actual mold soap from Laguna....... https://www.theceramicshop.com/product/2546/pure-lube-mold-soap-1-gallon/

lieuz

Chumono

Good to know. Thank you!!Murphy's Soap is technically a cleaning vegetable oil.

I use an actual mold soap from Laguna....... https://www.theceramicshop.com/product/2546/pure-lube-mold-soap-1-gallon/

lieuz

Chumono

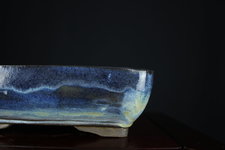

Nice job on the glaze.Pots have been fully fired and of the two, one is glazed and the other isn't here are the final products.

Size comparison.

View attachment 419525

Size comparison.

View attachment 419532

Glazed comparison.

View attachment 419526

Front

View attachment 419527

Side

View attachment 419529

Close up.

View attachment 419528

Close up.

View attachment 419530

Overview.

View attachment 419531

Pitoon

Imperial Masterpiece

Good job on those two!Pots have been fully fired and of the two, one is glazed and the other isn't here are the final products.

Size comparison.

View attachment 419525

Size comparison.

View attachment 419532

Glazed comparison.

View attachment 419526

Front

View attachment 419527

Side

View attachment 419529

Close up.

View attachment 419528

Close up.

View attachment 419530

Overview.

View attachment 419531

Similar threads

- Replies

- 3

- Views

- 224